Vibratory Stress Relieving (VSR)

When welded fabrications, castings, or machined components are put into service, the last thing you need is distortion, cracking, or premature failure caused by residual stress. At Stressweld, we provide a modern and effective solution: Vibratory Stress Relieving (VSR).

Our service can be carried out in your works or at Stressweld, giving you total flexibility. Using our full automatic VSR machine, we offer a cost-effective, efficient, and environmentally friendly alternative to thermal stress relief – ideally suited for situations where thermal heat treatment is not practical or where component design, size, or location make furnace treatment impossible.

Why Stress Relieving Is Essential

Whenever metal is welded, cast, or heavily machined, stresses are locked into the structure. These residual stresses can lead to:

- Distortion during machining

- Difficulty holding tight tolerances

- Reduced fatigue life

- Cracks or unexpected failure in service

Stress relieving redistributes these stresses, extending the life of the component and ensuring dimensional stability. Traditionally, this has been achieved by heating the entire structure in a furnace. But thermal treatment is costly, time-consuming, and often impractical – especially for large or complex assemblies.

That’s why more and more industries are choosing Vibratory Stress Relieving from Stressweld.

What Is Vibratory Stress Relieving?

VSR uses controlled, low-frequency vibrations to relieve stresses within a component. By exciting the structure at its natural resonant frequencies, internal stresses are safely redistributed – without the need for heating.

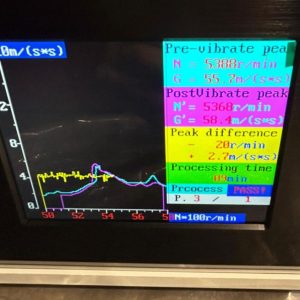

Our full automatic VSR machine continuously monitors and adjusts vibration cycles, ensuring complete and repeatable results. The process is efficient, reliable, and does not alter the metallurgical properties of the material.

On completion, we supply digital certification to verify that the process has been carried out correctly, giving you confidence and full traceability for quality assurance systems.

The Stressweld Advantage

Choosing Stressweld means working with specialists who understand not just the equipment, but the engineering science behind stress relieving.

Stressweld – Relieving the Stress in Your Components

Residual stress is invisible – but its consequences are not. Don’t let it compromise the quality, accuracy, or reliability of your work. With Stressweld’s Vibratory Stress Relieving service, you get a safe, economical, and certified solution. Whether you need work done in our factory or on your site, we deliver the results you need – quickly, reliably, and cost-effectively.

Get in Touch

Contact our team today to discuss your project and discover how Stressweld Ltd can deliver cost-effective, high-quality solutions tailored to your business.